Production

Temax Xps is produced by extrusion of polystyrene granules. Polystyrene is used in the production of household appliances, food service packaging, medical applications and even toys, which proves it is a safe material. Temax Xps production turns every tiny little granule of polystyrene into a reliable and energy-efficient thermal insulation material.

- Before being processed, all the raw materials need to pass quality control after which the polystyrene granules and other components are sent for storage in special reservoirs – silos.

- From these reservoirs, the raw materials go to the main production unit – the extruder. Here, at a certain temperature and pressure, the polystyrene granules are mixed with special additives and foaming agents. The resulting product, a compact foam mass, is a material that goes for further treatment.

- The thickness of Temax Xps material is defined by the calibrator and lies between 20mm and 120mm. After extrusion, XPS possesses a close pore structure, air is locked and sealed in pores of polystyrene, the size of which is less than 0.2mm. Such material structure guarantees high heat savings, high strength properties and low water absorption.

- After that, the material goes to the cutting unit, where the primary dimensions of a board are defined and the length of the board is determined.

- For advanced adhesion of XPS to other materials, the board is milled to form different surface models, such as rough, waffled, or grooved surfaces.

- Then, the material goes to the print unit, where the print is applied to the surface.

- The next step is the milling cutter unit. Here the "I" straight edges or "L" shaped edges are formed.

- All cut-offs obtained after edge formation and milling are then collected by the automatic system and recycled into granules that will be reused in the production process. Such technology enables zero-waste and ecologically friendly production of Temax XPS.

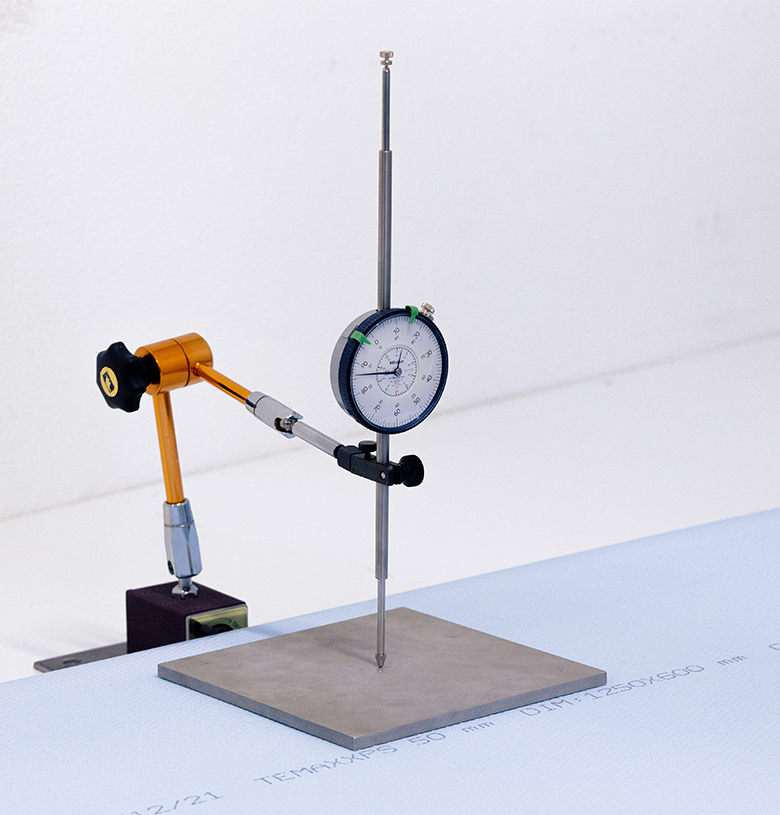

- During production, every 1 to 2 hours, samples of the material are tested by the quality control management. They test the claimed values of thermal conductivity, water absorption, compressive strength, and geometric parameters of the sample. Only when the tests are passed successfully is Temax XPS allowed to continue to the next step, which is packaging.

- Packages of the separate boards go on the package unit, where the products get covered with heat-shrinkable film and then stacked on pallets. Final pallets are then additionally covered with a stretch film, which protects the material from external factors during long-term storage outdoors or in storage facilities.

- After packaging, the product is then transported to the storage facility.