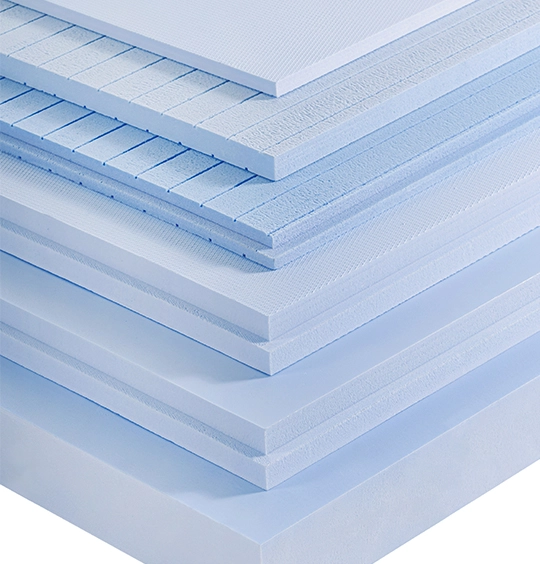

What is XPS?

Polystyrene is a synthetic insulation material that can be found in many forms, but extruded polystyrene (XPS) remains the most popular thanks to its high thermal insulation efficacy. Made of closed-cell foam, extruded polystyrene material is widely used for thermal insulation of residential buildings on all construction levels, starting from the basement to the roof. It is also widely used in the form of panel boards in the PVC and ALU industries, and it is applied to industrial objects and road facilities. Thanks to the density of its closed-cell composition, extruded polystyrene (XPS) has exceptional resistance to water and water vapor. It is also designed to perform in all applications, even in areas exposed to moisture, such as underground walls and inverted roofs. It is versatile and can withstand extreme temperature changes and freeze-thaw cycles without permanent damage. Moreover, it has high compressive strength and is chemically resistant, so even when exposed to moisture, it resists mold and bacteria. Thanks to these features, extruded polystyrene (XPS) is highly ranked as one of the leading materials in the thermal insulation industry.

Superior Properties of XPS

- Low thermal conductivity

- Continuous and non-decreasing λ- thermal conductivity value

- Frost resistant

- Low water absorption and high tolerance of wet environments

- High compressive strength which does not decrease over time.

- High modulus of elasticity and stability

- 100% recyclable, zero waste material

- Eco friendly, it uses CO2 technology

- Ecological compatibility and durability

- Closed-cell structure

- Does not shrink or swell

- Has chemical and biological resistance

- Excellent energy-saving performance

Short History of XPS

The first Extruded Polystyrene Foam was produced in the early 1940s for floating lifeboats as a demand of the USA for military purposes. As a result of its intensive use, these products which are highly resistant to water and humidity, have also been noticed due to their thermal insulation technical features. So, furthermore they have been used for producing thermal insulation materials. Extruded Polystyrene boards, which started to be manufactured in Europe in the 1960s, have been used safely in all buildings and engineering structures for more than 50 years. Today, the use of the Extruded Polystyrene Boards worldwide is around 15-20 million m3/year.

Why Should We Use XPS?

The decrease of energy resources in the world and global warming have made it necessary for all countries to take their energy consumption under control and to develop effective methods of energy use. Most of the energy usage in residential buildings is for heating and cooling purposes. Efficient usage of energy can be mostly achieved with good thermal insulation. Creating healthy living conditions while reducing energy consumption helps the consumers make heating and cooling with low energy costs and therefore reduce air pollution. The purpose of XPS is to reduce the temperature loss between the building components and the external environment. XPS increases the lifetime and value of buildings while protecting them at the same time. Providing comfortable living conditions is crucial for human health, and insulating the buildings is an important aspect that helps improve these conditions, and grants greater living comfort.

Advantages of XPS

- Saves energy

- It is great for protecting the building from internal and external climatic factors.

- Eco friendly

- Keeps the buildings cool in the summer and warm in the winter.

- Protects the building from condensation and corrosion.

- Protects the building from cracks due to temperature changes.

- It is a thinner material in comparison to other thermal insulation materials.

- Thanks to its durability, XPS is practical for the construction of roofs and floors.

- Apart from construction, it is also used in other industries.

- It is lightweight and easy to work with.